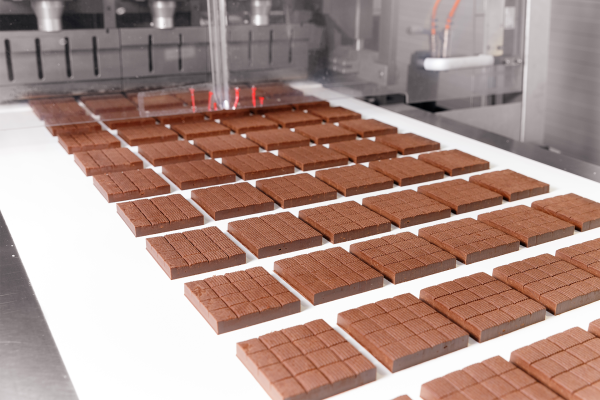

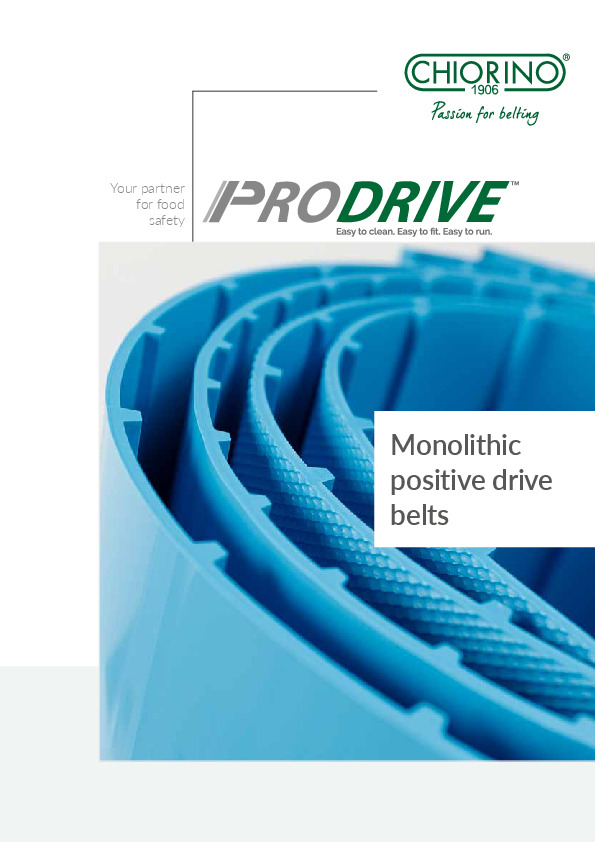

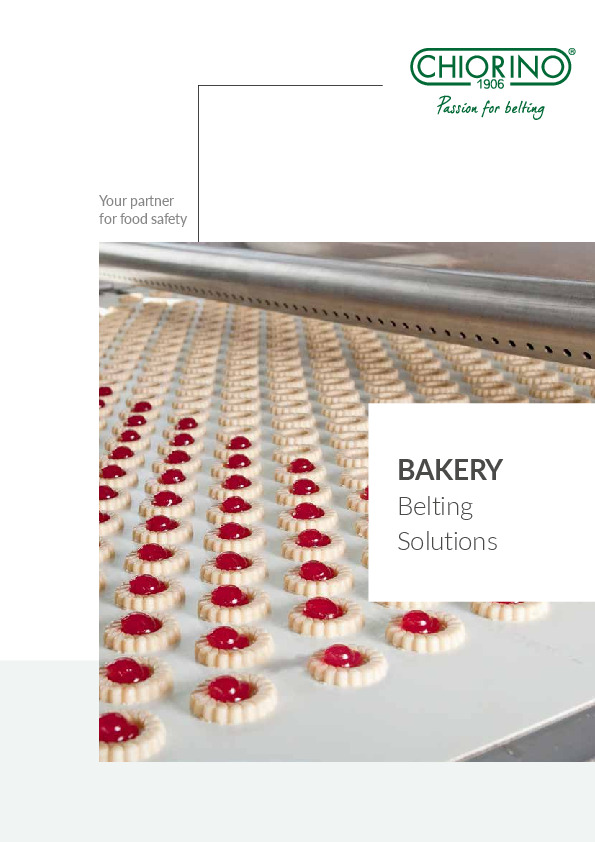

Bakery

at the forefront of the bakery industry evolution

Chiorino continues to lead the way in the food industry with belting solutions that fully meet the requirements of the bakery processing and packaging industry, performing outstandingly and overcoming today’s challenges, in compliance with the rising hygienic and food safety standards.

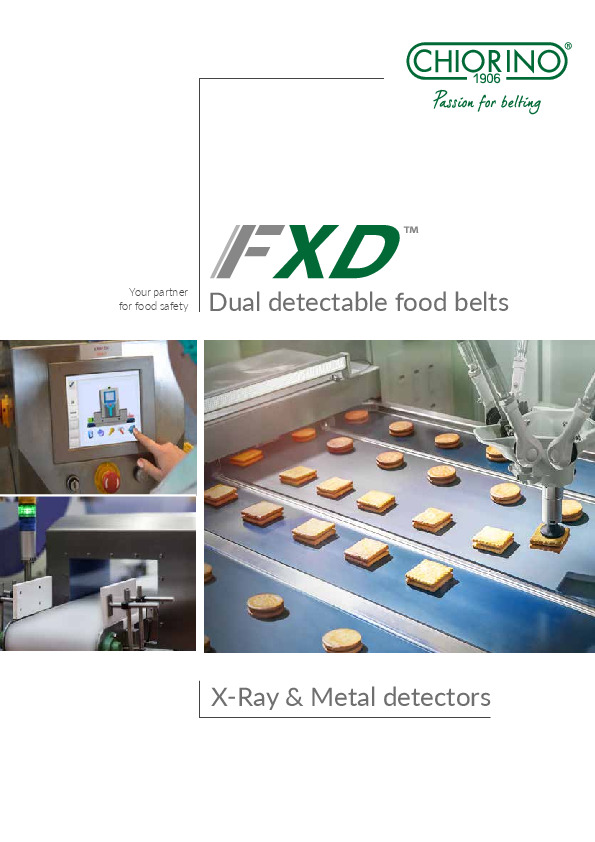

Food Safety

and Hygiene

Optimized Cost

of Ownership

Risk

Management

Production

Efficiency

Sustainability

Industry 4.0

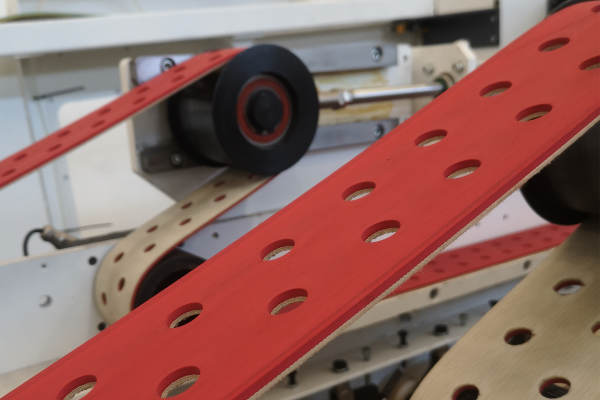

processes and applications

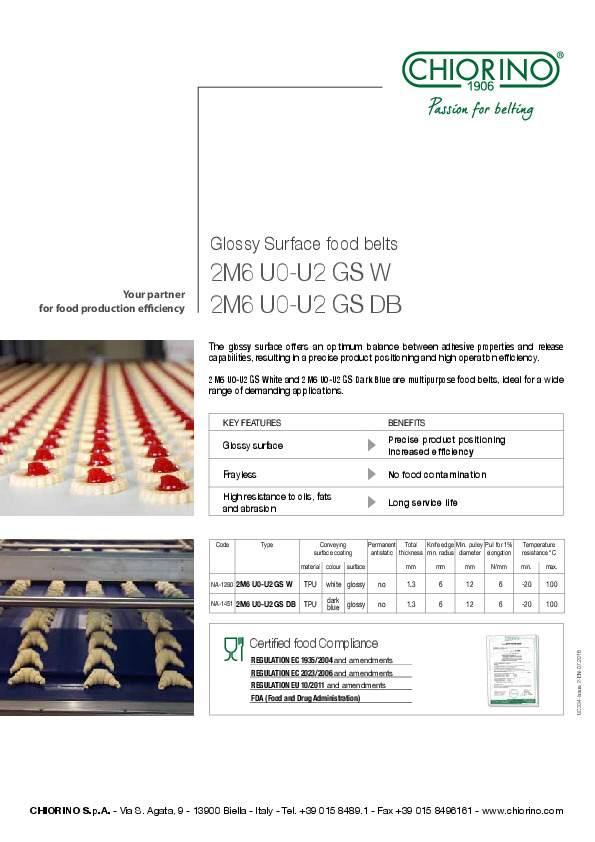

Chiorino belting solutions are developed to provide the best resistance to cut, abrasion, fats, oils and high temperature, guaranteeing production efficiency, longer service life, product safety and cost savings.

Main processes:

- Mixer

- Former

- Proofer

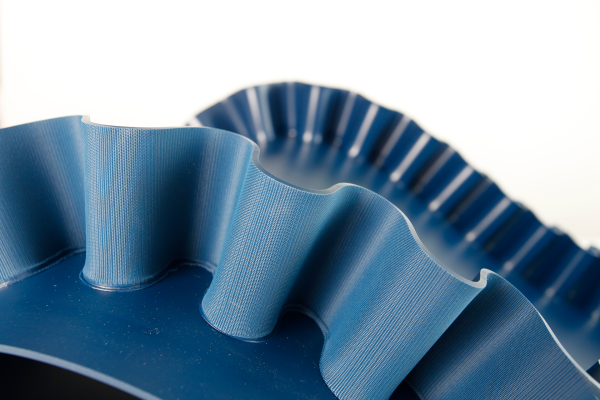

- Curve belt

- Oven

- Cooling

- Packaging

- Control

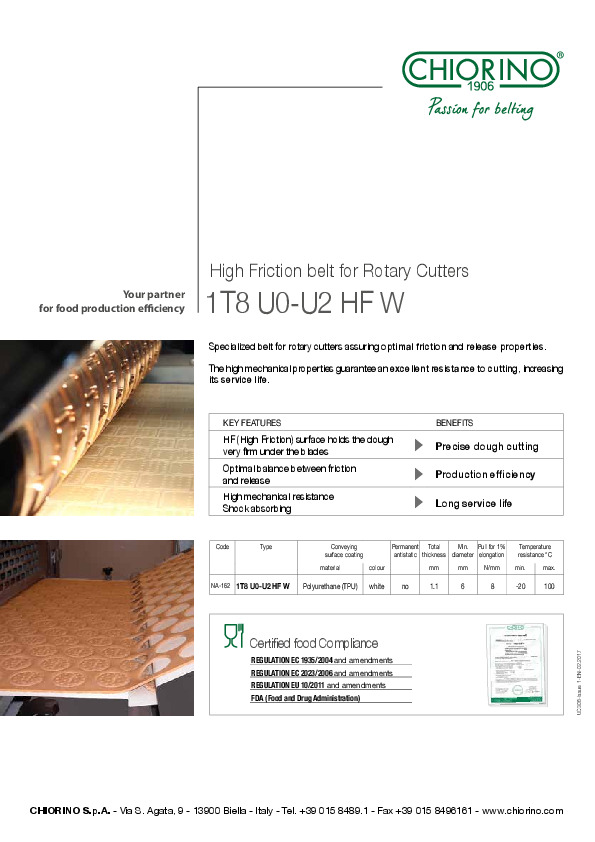

Chiorino belting solutions are developed to provide the best resistance to cut, abrasion, fats, oils and high temperature, guaranteeing production efficiency, longer service life, product safety and cost savings.

Main processes:

- Feeder

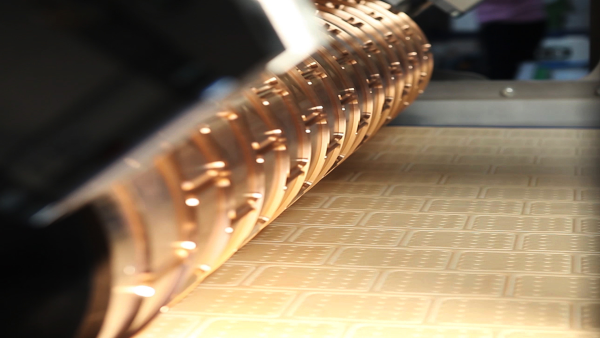

- Rotary moulder

- Gauge rollers

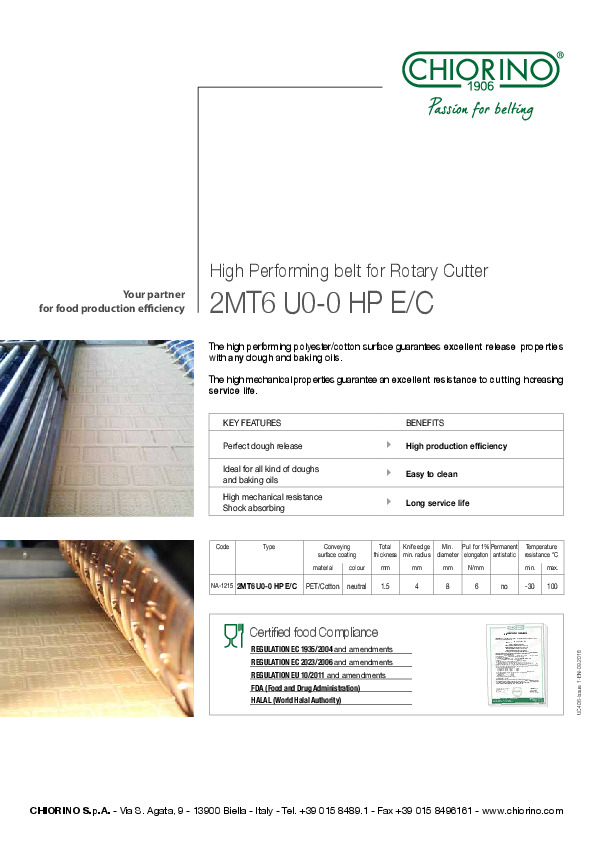

- Rotary cutter

- Scrap return

- Oven

- Curve belts

- Cooling

- Packaging

- Control

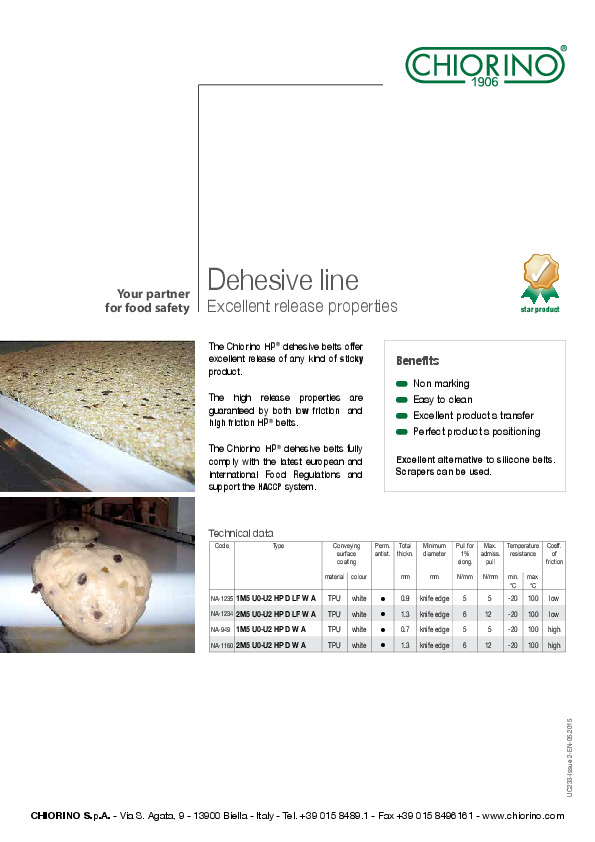

Chiorino belting solutions are developed to provide a superior resistance to aggressive fats, oils and to extreme temperature, guaranteeing excellent release properties to reduce product waste, increase production efficiency, product safety and a longer service life.

Main processes:

- Mixer

- Sheeter

- Forming line

- Oven

- Cooling

- Packaging

- Control

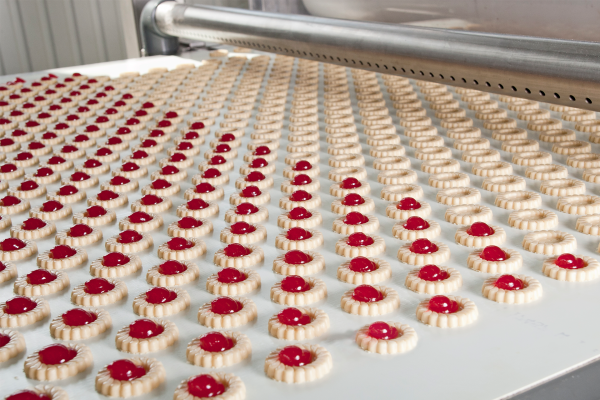

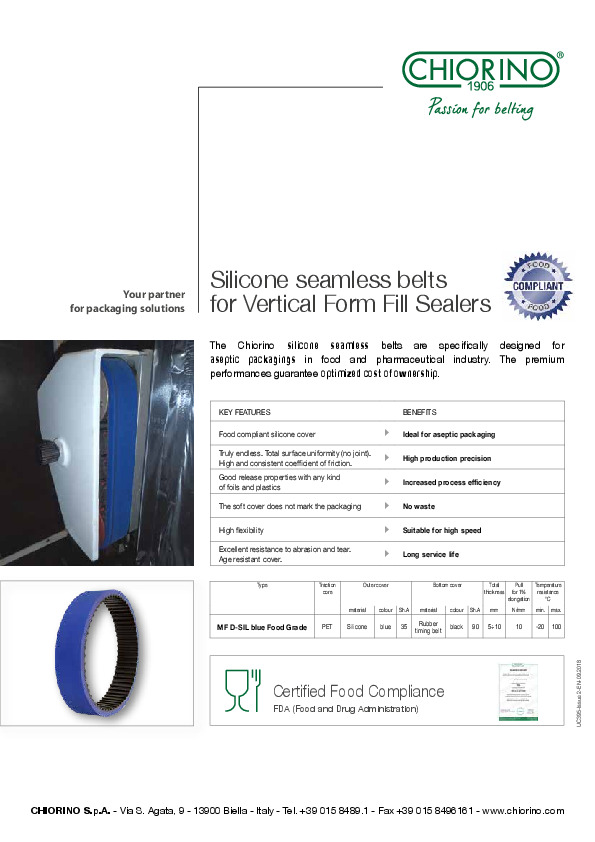

Chiorino belting solutions are developed to provide a superior resistance to cut, abrasion, aggressive fats, oils and extreme temperature, guaranteeing excellent release properties, production efficiency, product safety and a longer service life.

Main processes:

- Mixer

- Former

- Gauge rollers

- Rotary cutter

- Scrap return

- Transfer to depositor

- Depositor

- Oven

- Curve belt

- Packaging

- Control