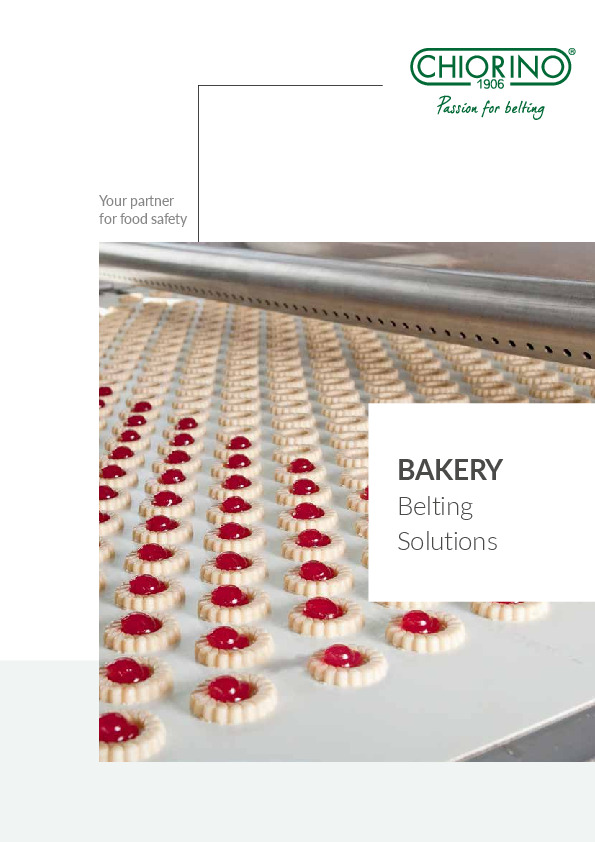

Sütőipar

a sütőipar fejlődésének élén&

A Chiorino továbbra is élen jár az élelmiszeriparban, a sütőipari feldolgozó- és csomagolási követelményeknek maradéktalanul megfelelő hevederes megoldásaival, kiemelkedően teljesítve és a mai kihívásokat felülmúlva’ a növekvő higiéniai és élelmiszerbiztonsági előírásoknak megfelelően.

Biztonságos

és Higiénikus

Optimalizált költségek

a tulajdonosok számára

Kockázat

kezelés

Hatékony

Termelés

Fenntarthatóság

Ipar 4.0

folyamatok és alkalmazások

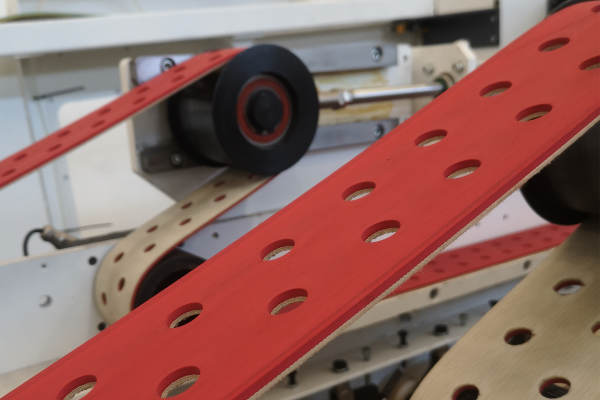

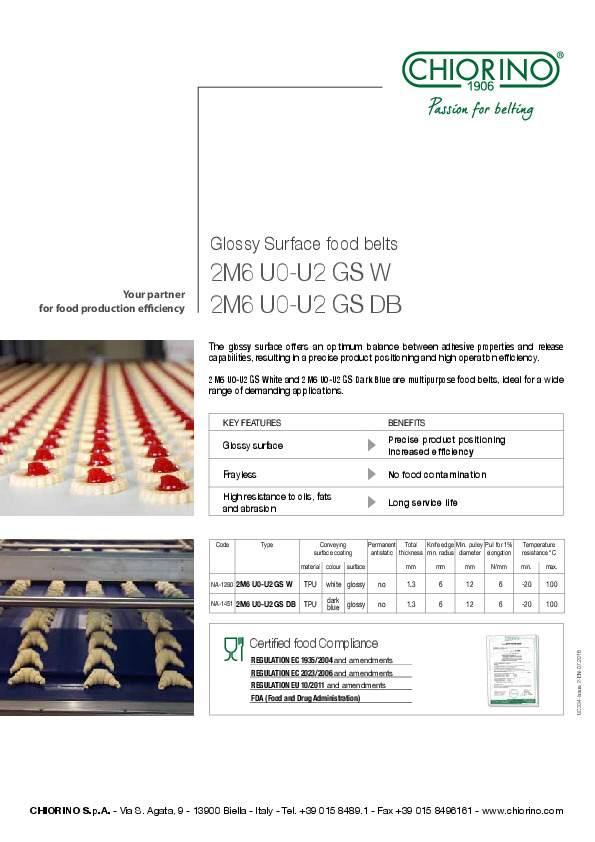

Chiorino belting solutions are developed to provide the best resistance to cut, abrasion, fats, oils and high temperature, guaranteeing production efficiency, longer service life, product safety and cost savings.

Main processes:

- Mixer

- Former

- Proofer

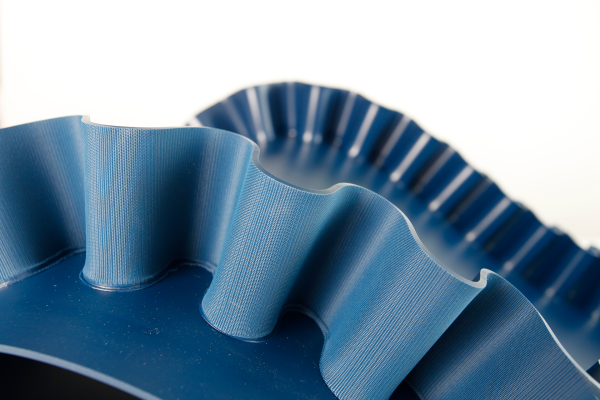

- Curve belt

- Oven

- Cooling

- Packaging

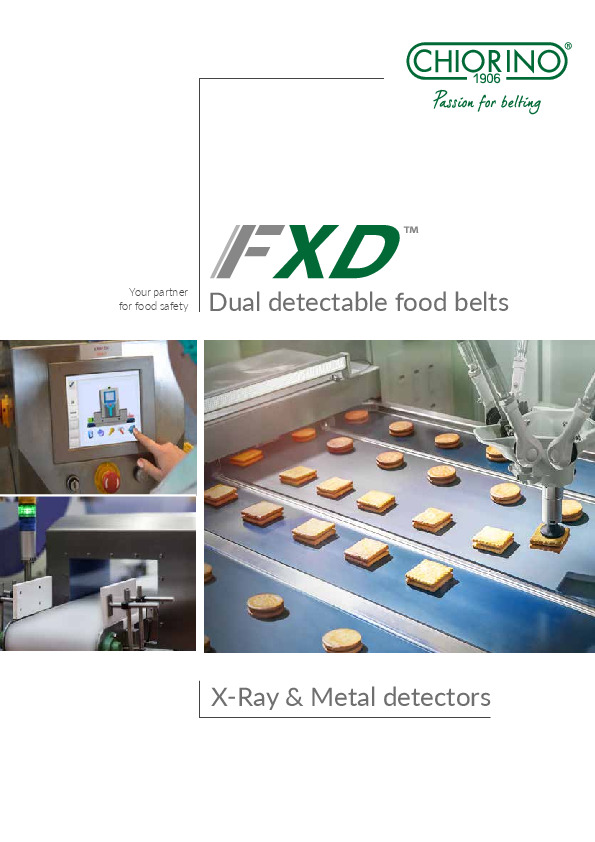

- Control

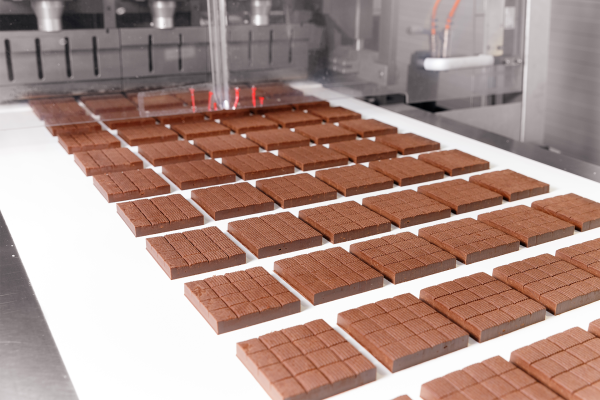

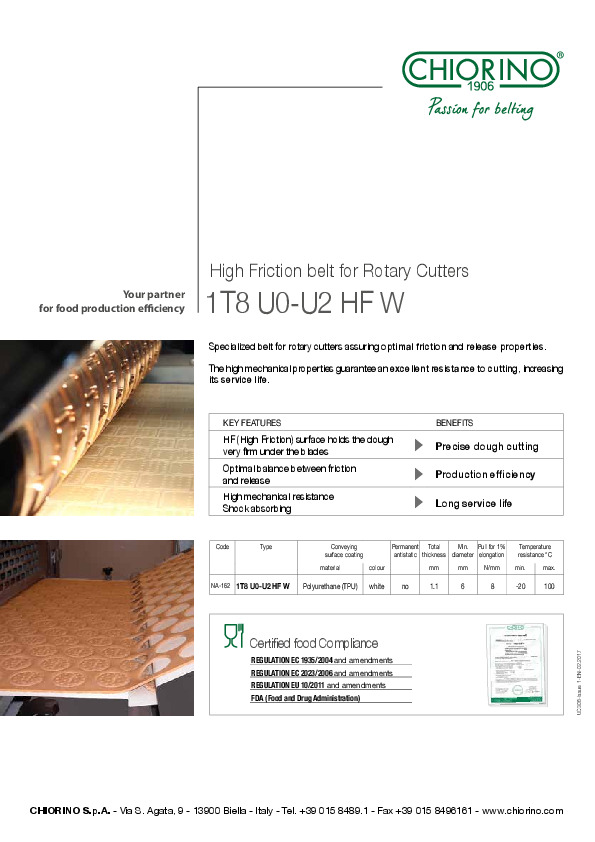

Chiorino belting solutions are developed to provide the best resistance to cut, abrasion, fats, oils and high temperature, guaranteeing production efficiency, longer service life, product safety and cost savings.

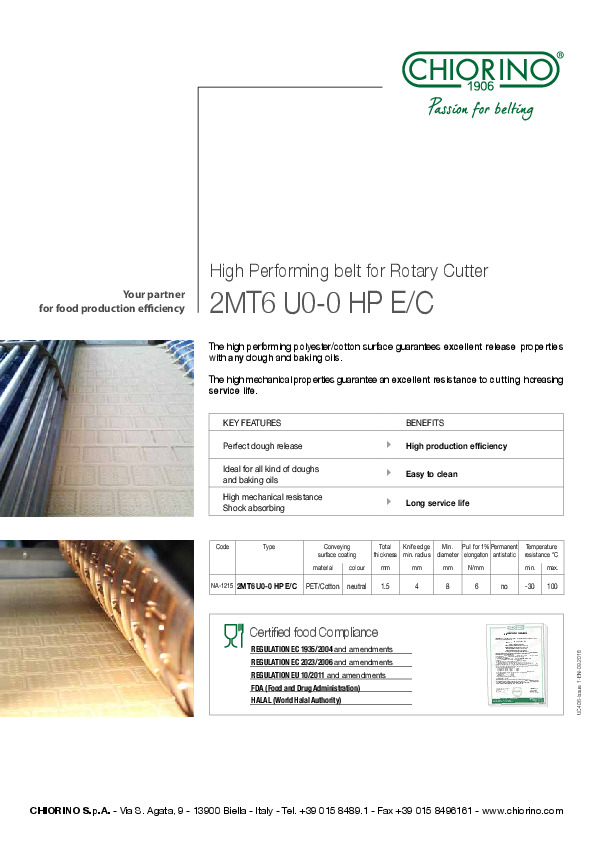

Main processes:

- Feeder

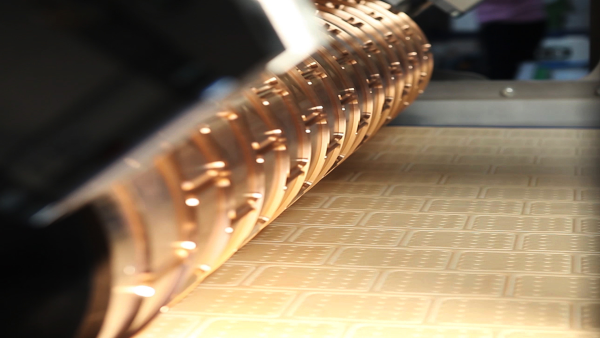

- Rotary moulder

- Gauge rollers

- Rotary cutter

- Scrap return

- Oven

- Curve belts

- Cooling

- Packaging

- Control

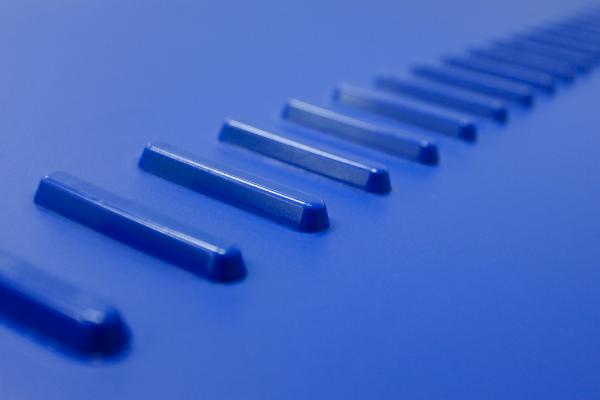

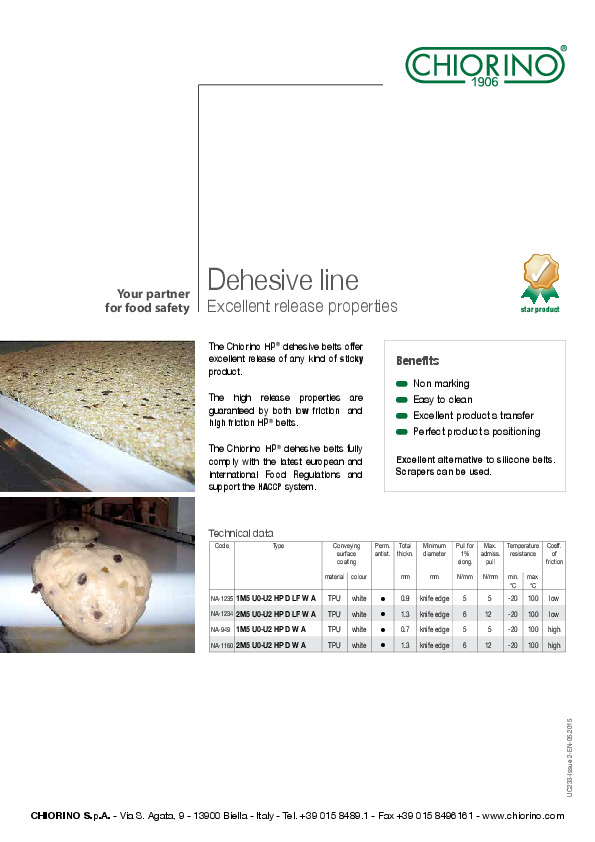

Chiorino belting solutions are developed to provide a superior resistance to aggressive fats, oils and to extreme temperature, guaranteeing excellent release properties to reduce product waste, increase production efficiency, product safety and a longer service life.

Main processes:

- Mixer

- Sheeter

- Forming line

- Oven

- Cooling

- Packaging

- Control

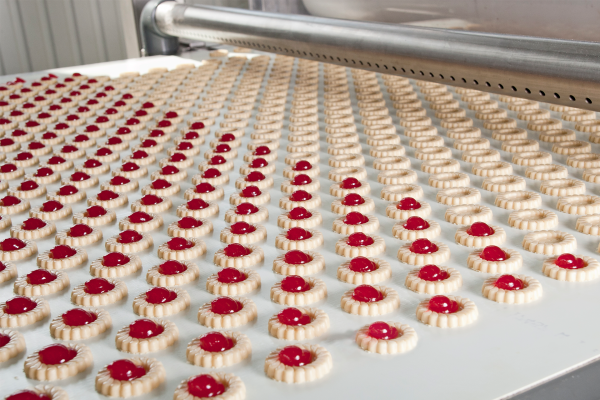

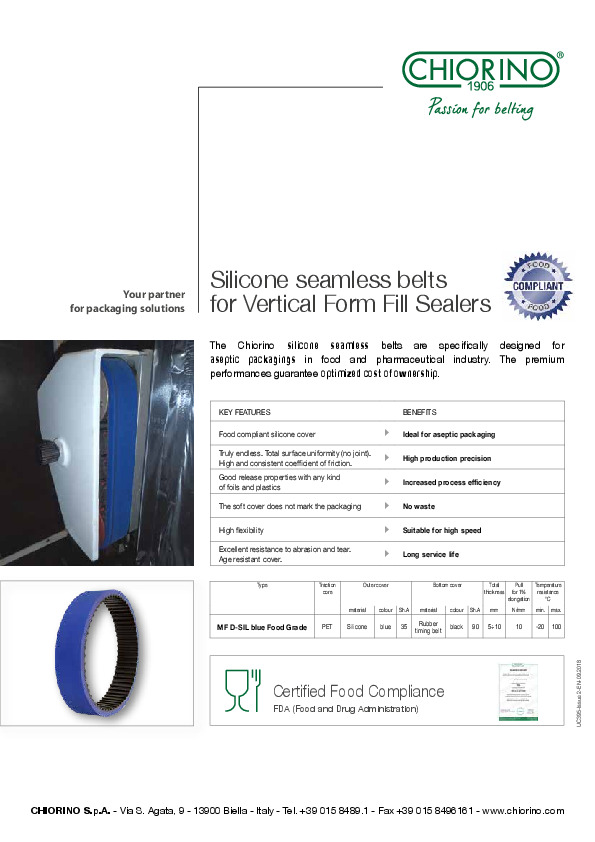

Chiorino belting solutions are developed to provide a superior resistance to cut, abrasion, aggressive fats, oils and extreme temperature, guaranteeing excellent release properties, production efficiency, product safety and a longer service life.

Main processes:

- Mixer

- Former

- Gauge rollers

- Rotary cutter

- Scrap return

- Transfer to depositor

- Depositor

- Oven

- Curve belt

- Packaging

- Control