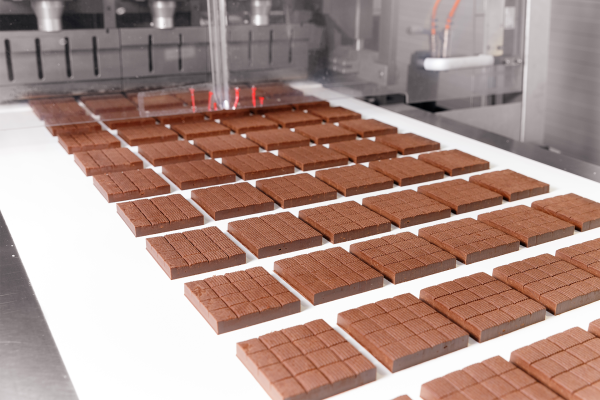

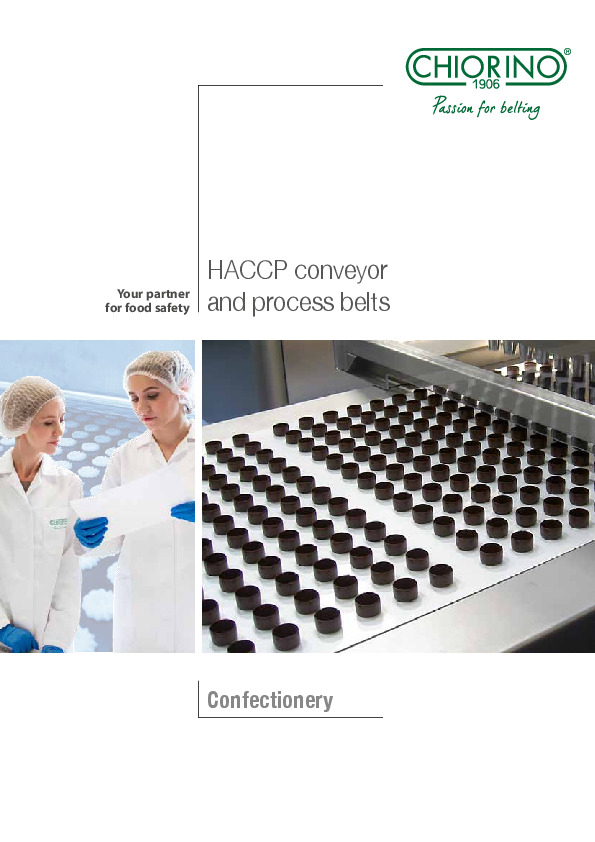

Chocolate and Confectionery

at the forefront of the chocolate and confectionery industry evolution

Chiorino continues to lead the way in the food industry with belting solutions that fully meet the requirements of the chocolate and confectionery processing and packaging industry, performing outstandingly and overcoming today’s challenges, in compliance with the rising hygienic and food safety standards.

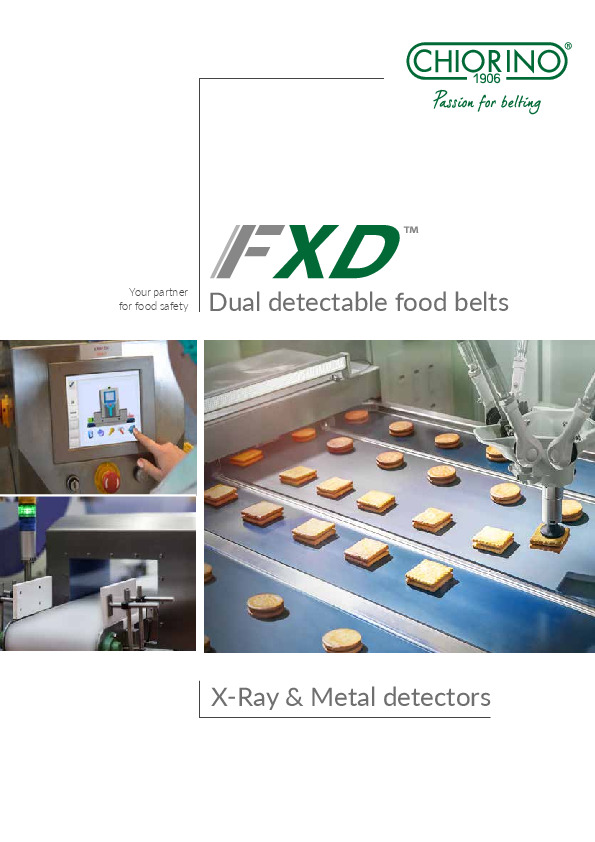

Food Safety

and Hygiene

Optimized Cost

of Ownership

Risk

Management

Production

Efficiency

Sustainability

Industry 4.0

processes and applications

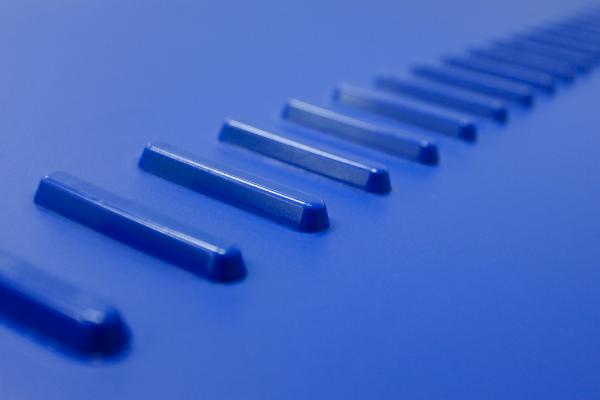

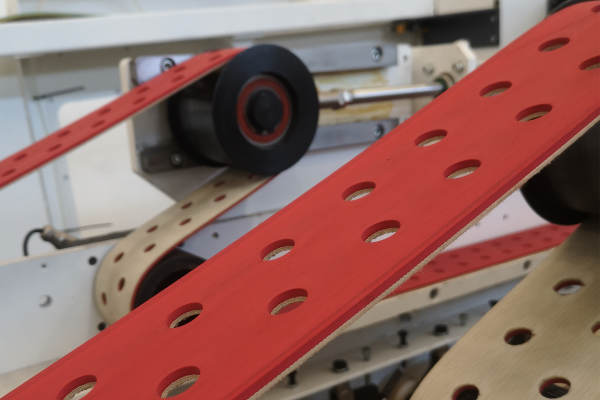

Chiorino belting solutions are developed to provide the best resistance to fats, oils, low temperatures and mechanical stress guaranteeing production efficiency, longer service life, product safety and an optimized cost of ownership.

Main processes:

- Cooling

- Cutter

- Spreaded belts

- Curve belts

- Metering

- Trasfer to packaging

- Packaging

- Weighing and control

Chiorino belting solutions are developed to provide the best resistance to fats, oils, low temperatures and mechanical stress guaranteeing production efficiency, longer service life, product safety and an optimized cost of ownership.

Main processes:

- Cooling

- Cutter

- Spreaded belts

- Curve belts

- Metering

- Trasfer to packaging

- Packaging

- Weighing and control

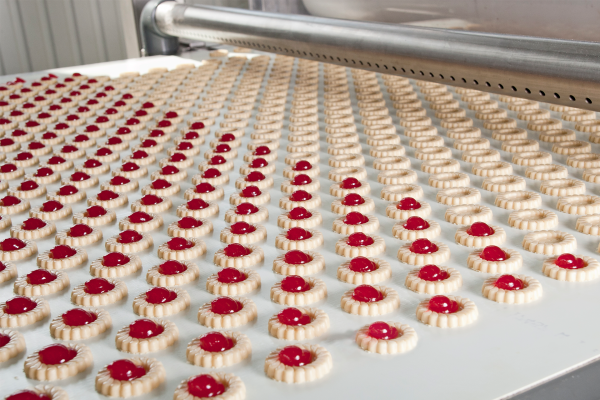

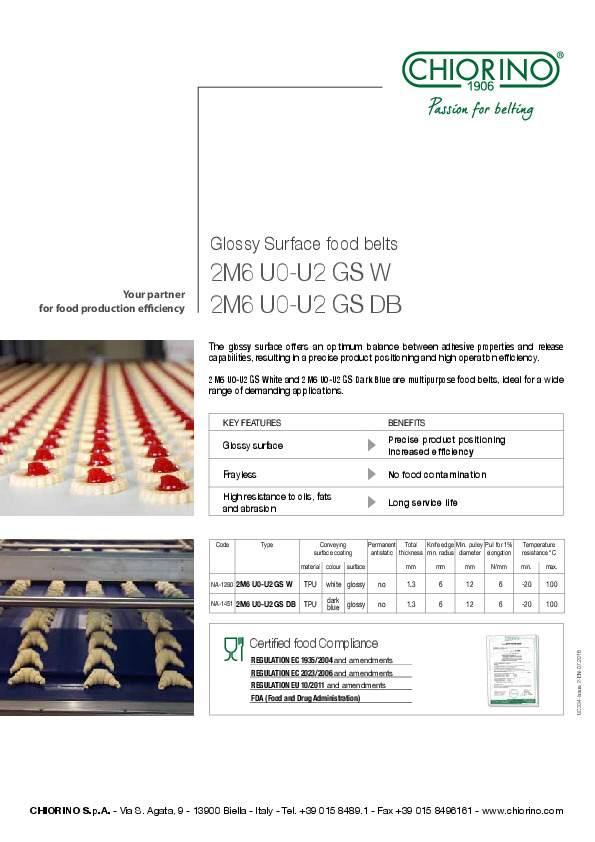

The wide range of Chiorino belting solutions guarantee excellent release properties and great precision in product positioning and transferring, with a superior resistance to fats, oils and low temperature. The result is higher production efficiency, reduced dowtimes and a longer belt service life.

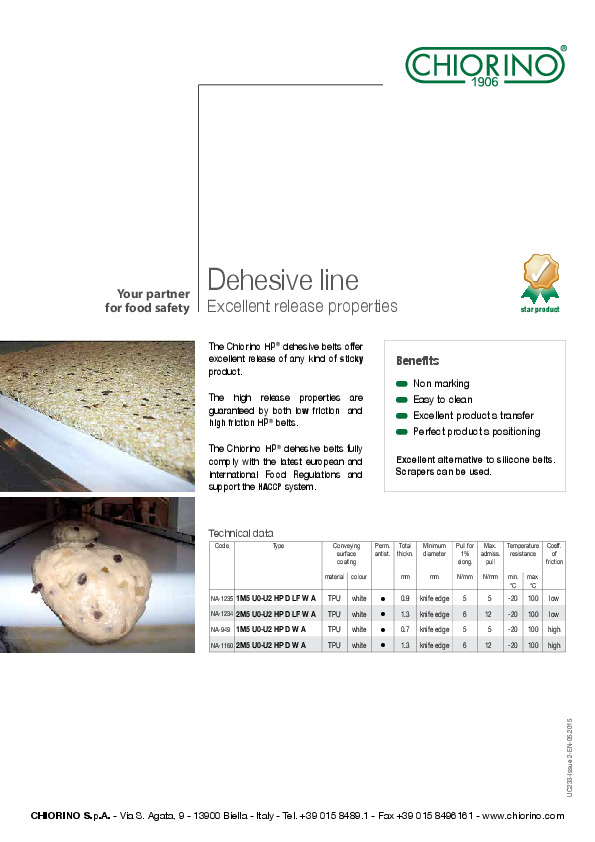

Chiorino belting solutions are developed to provide a superior resistance to aggressive fats, oils and to extreme temperature, guaranteeing excellent release properties to reduce product waste, increase production efficiency, product safety and a longer service life.

Main processes:

- Mixer

- Sheeter

- Forming line

- Oven

- Cooling

- Packaging

- Control