Cukrászat és csokoládé

csokoládé és édességipar fejlődésének élén

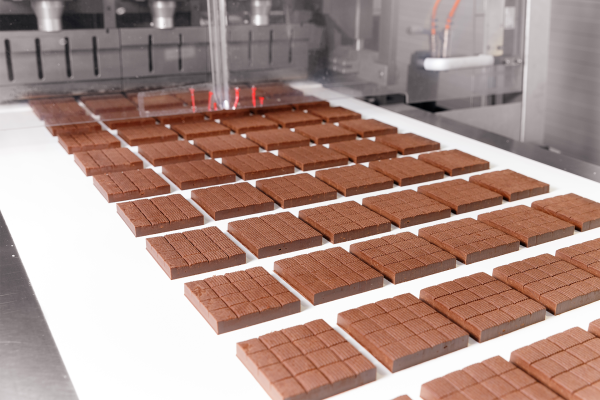

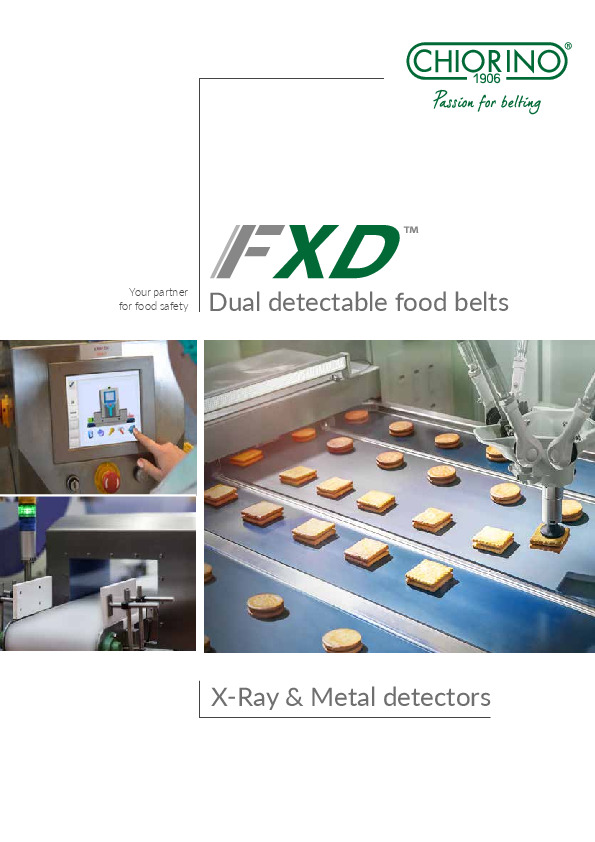

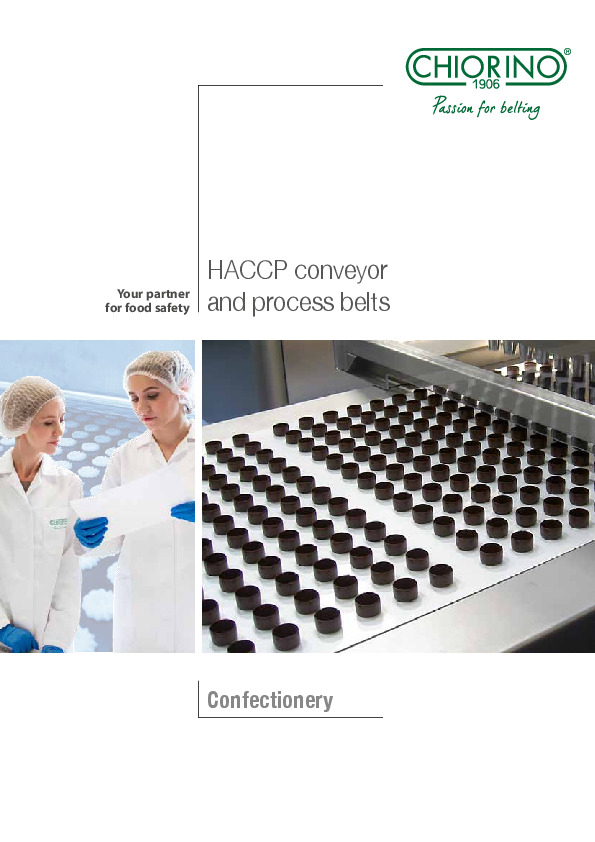

A Chiorino továbbra is élen jár az élelmiszeriparban, acsokoládé- és édesipari feldolgozó- és csomagolási követelményeknek maradéktalanul megfelelő hevederes megoldásaival, kiemelkedően teljesítve és a mai kihívásokat is leküzdve’ a növekvő higiéniai és élelmiszerbiztonsági előírásoknak megfelelően.

Biztonságos

és Higiénikus

Optimalizált költségek

a tulajdonosok számára

Kockázat

kezelés

Hatékony

Termelés

Fenntarthatóság

Ipar 4.0

folyamatok és alkalmazások

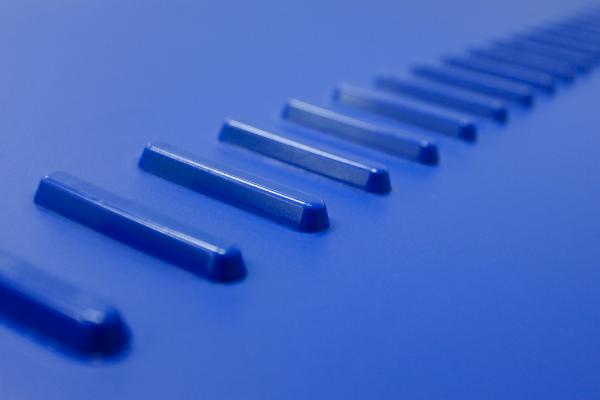

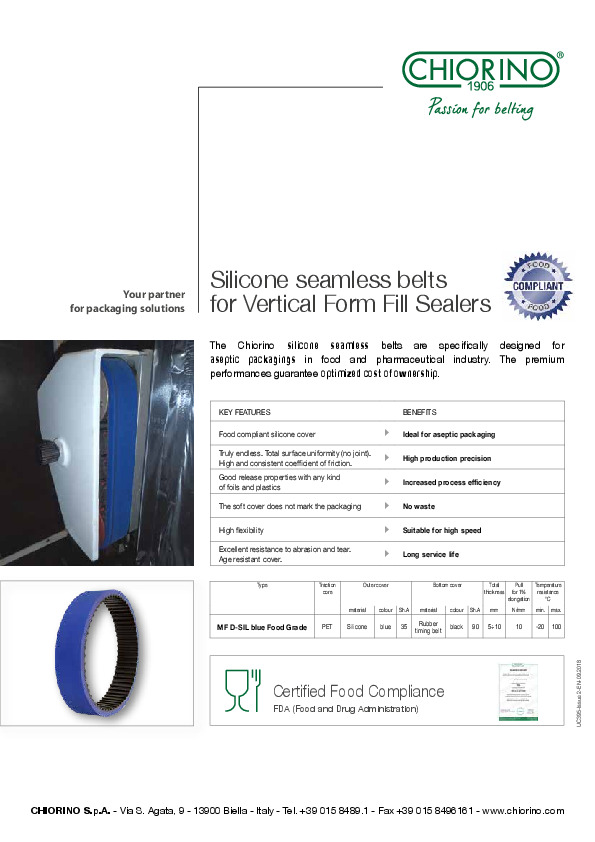

Chiorino belting solutions are developed to provide the best resistance to fats, oils, low temperatures and mechanical stress guaranteeing production efficiency, longer service life, product safety and an optimized cost of ownership.

Main processes:

- Cooling

- Cutter

- Spreaded belts

- Curve belts

- Metering

- Trasfer to packaging

- Packaging

- Weighing and control

Chiorino belting solutions are developed to provide the best resistance to fats, oils, low temperatures and mechanical stress guaranteeing production efficiency, longer service life, product safety and an optimized cost of ownership.

Main processes:

- Cooling

- Cutter

- Spreaded belts

- Curve belts

- Metering

- Trasfer to packaging

- Packaging

- Weighing and control

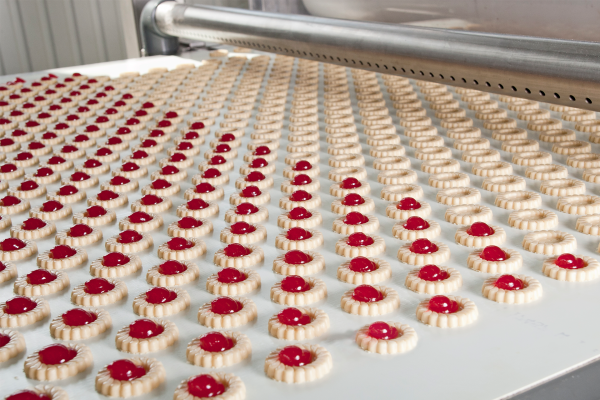

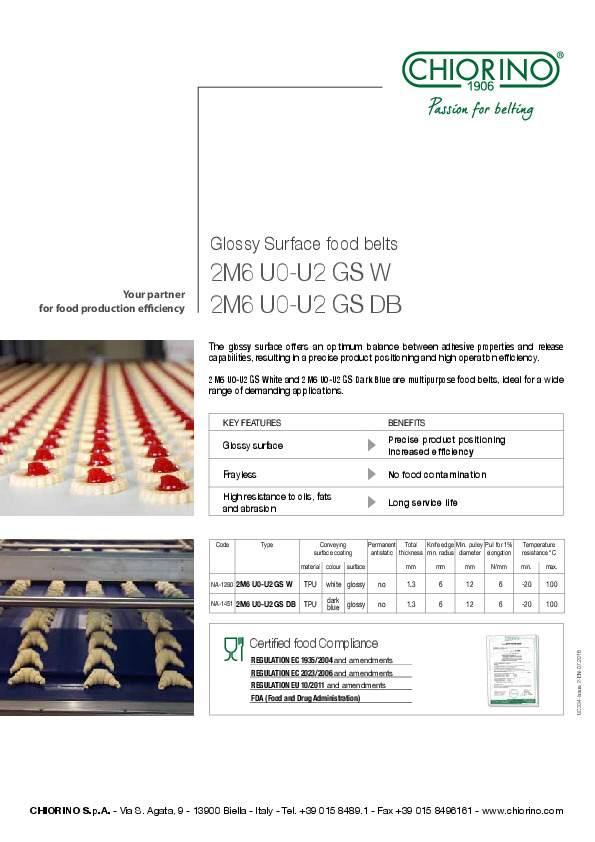

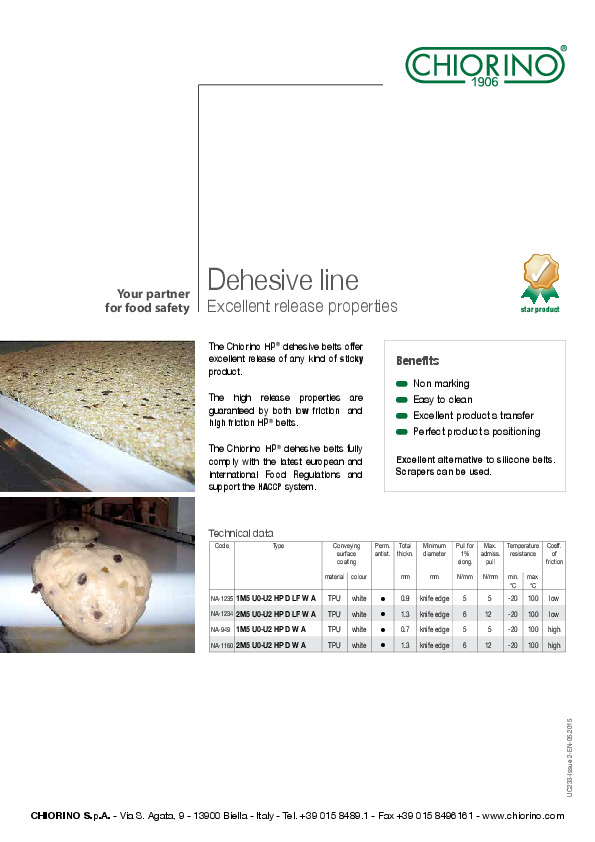

The wide range of Chiorino belting solutions guarantee excellent release properties and great precision in product positioning and transferring, with a superior resistance to fats, oils and low temperature. The result is higher production efficiency, reduced dowtimes and a longer belt service life.

Chiorino belting solutions are developed to provide a superior resistance to aggressive fats, oils and to extreme temperature, guaranteeing excellent release properties to reduce product waste, increase production efficiency, product safety and a longer service life.

Main processes:

- Mixer

- Sheeter

- Forming line

- Oven

- Cooling

- Packaging

- Control