Modulare Kunststoffbänder

Safari Belting Systems hat ULTRA-TUFF™ entwickelt, das einzigartige modulare Transportband, für eine sorgenfreie Anwendung. Es löst Probleme bei der Anlagenkonstruktion und der Anwendung, bei denen herkömmliche Kunststoffe aufgrund ihrer Stoßfestigkeit, Chemikalienbeständigkeit, Reibungskoeffizienten und/oder Hitzebeständigkeit nicht optimal sind.

ULTRA-TUFF™ ist ein „umweltfreundliches“ Polymer, dessen Hauptstrang nur aus Kohlenstoff besteht. Es ist hochkristallin mit einer kompakten Kristallstruktur, was zu einer unübertroffenen Schlag-, Chemikalien- und Abriebfestigkeit führt.

ULTRA-TUFF™ ist das einzige modulare Kunststoffband auf dem Markt, das gleichzeitig hohen Aufprallbelastungen, längerem Kontakt mit aggressiven Chemikalien (einschließlich PAA) und übermäßigem Verschleiß durch Reibung und/oder Abrieb standhält.

ULTRA-TUFF™ ist auch in einer Metall- und Röntgen-erkennbaren (XMD) Version erhältlich.

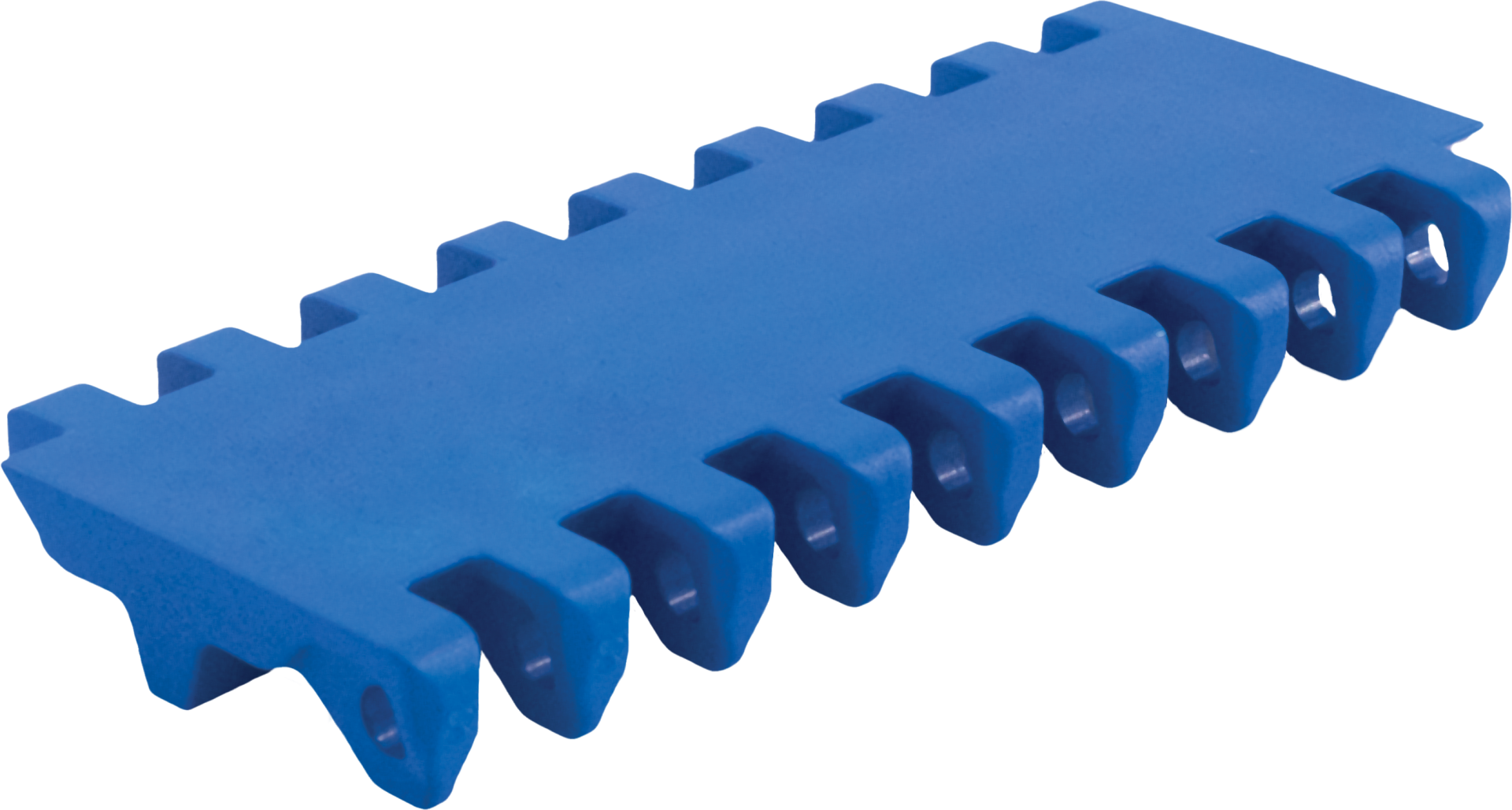

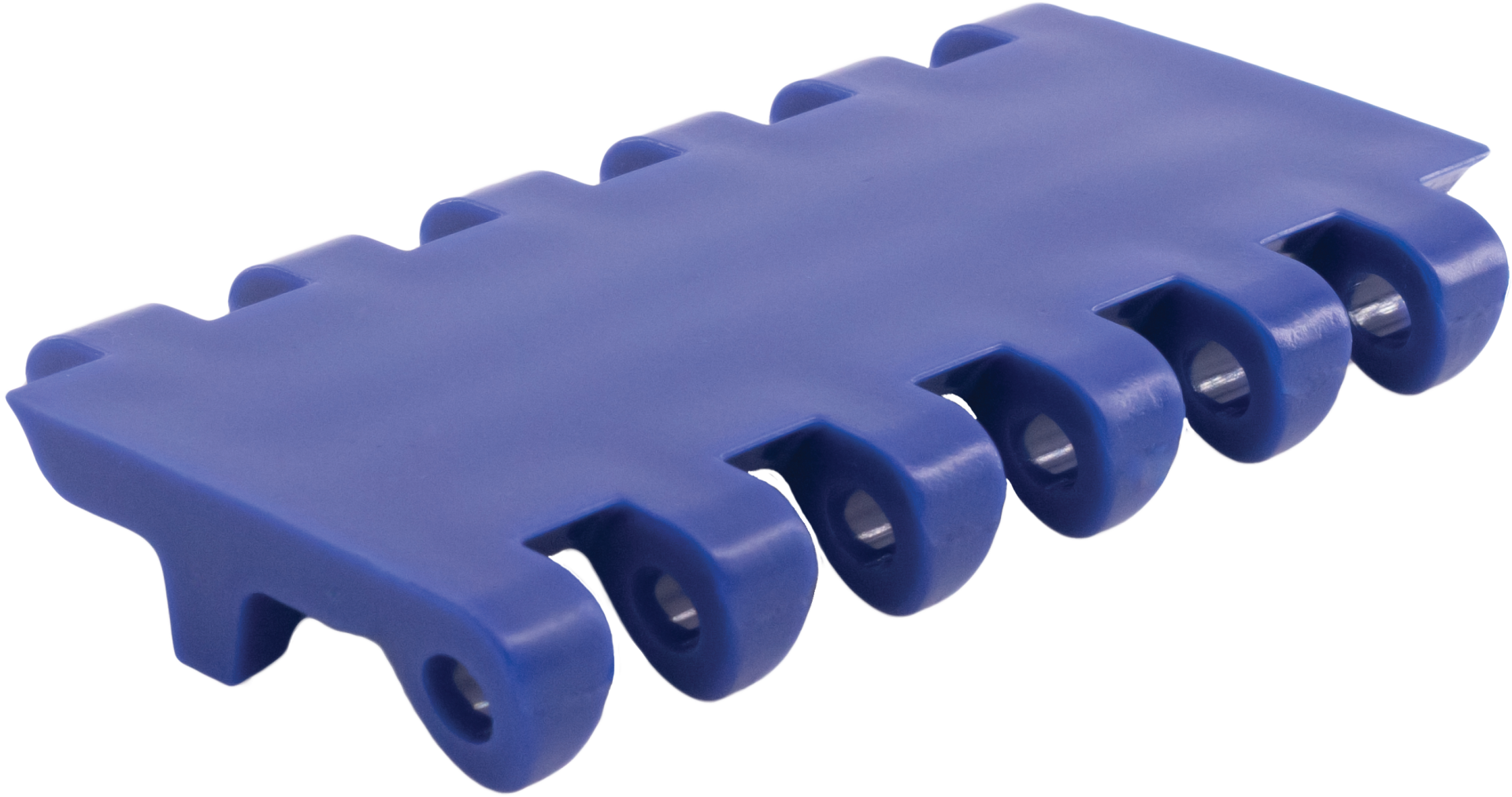

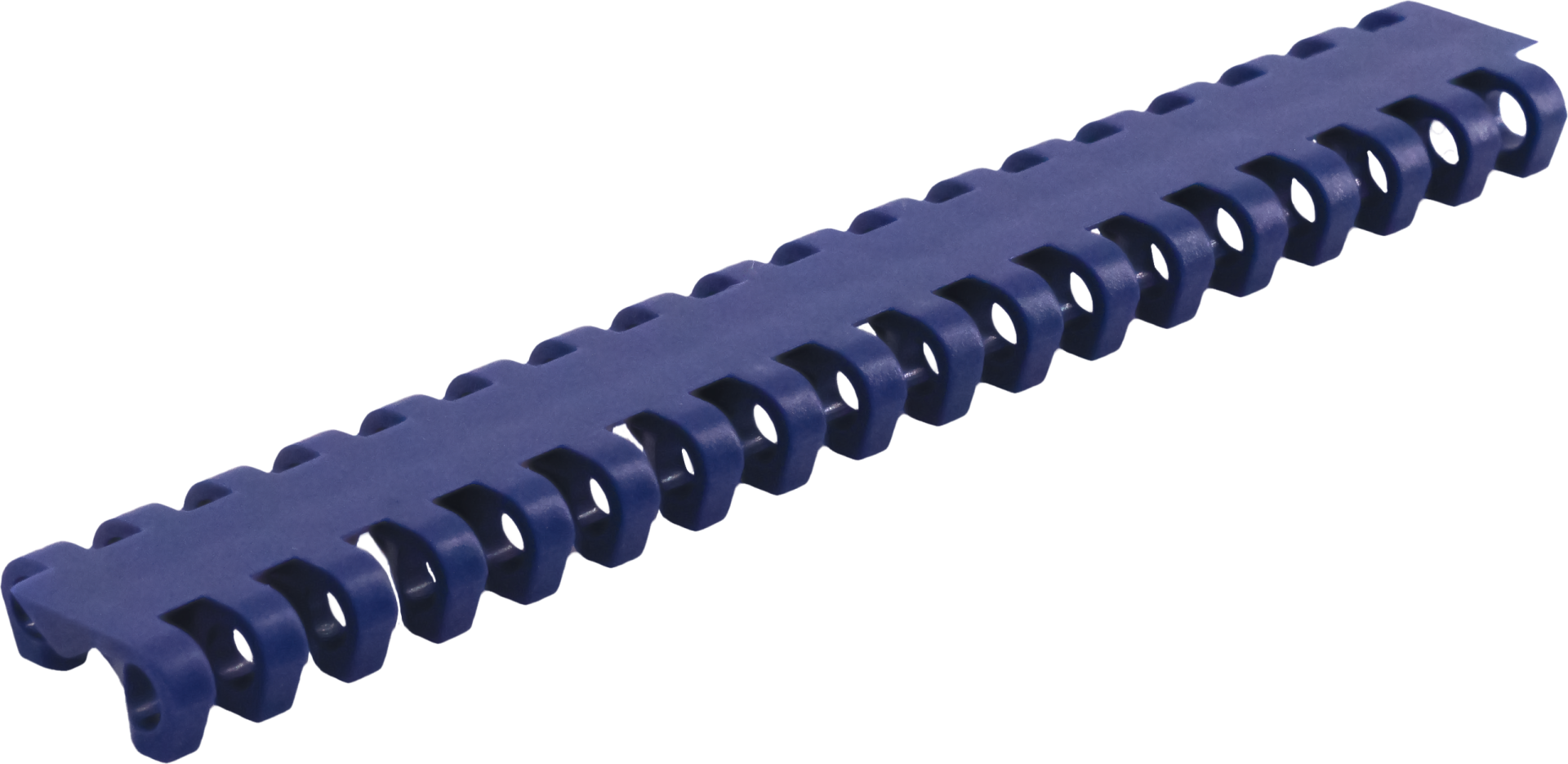

Standard Duty 1.07” (27.2 mm) Pitch

Standard Duty 1.0” (25.4 mm) Pitch

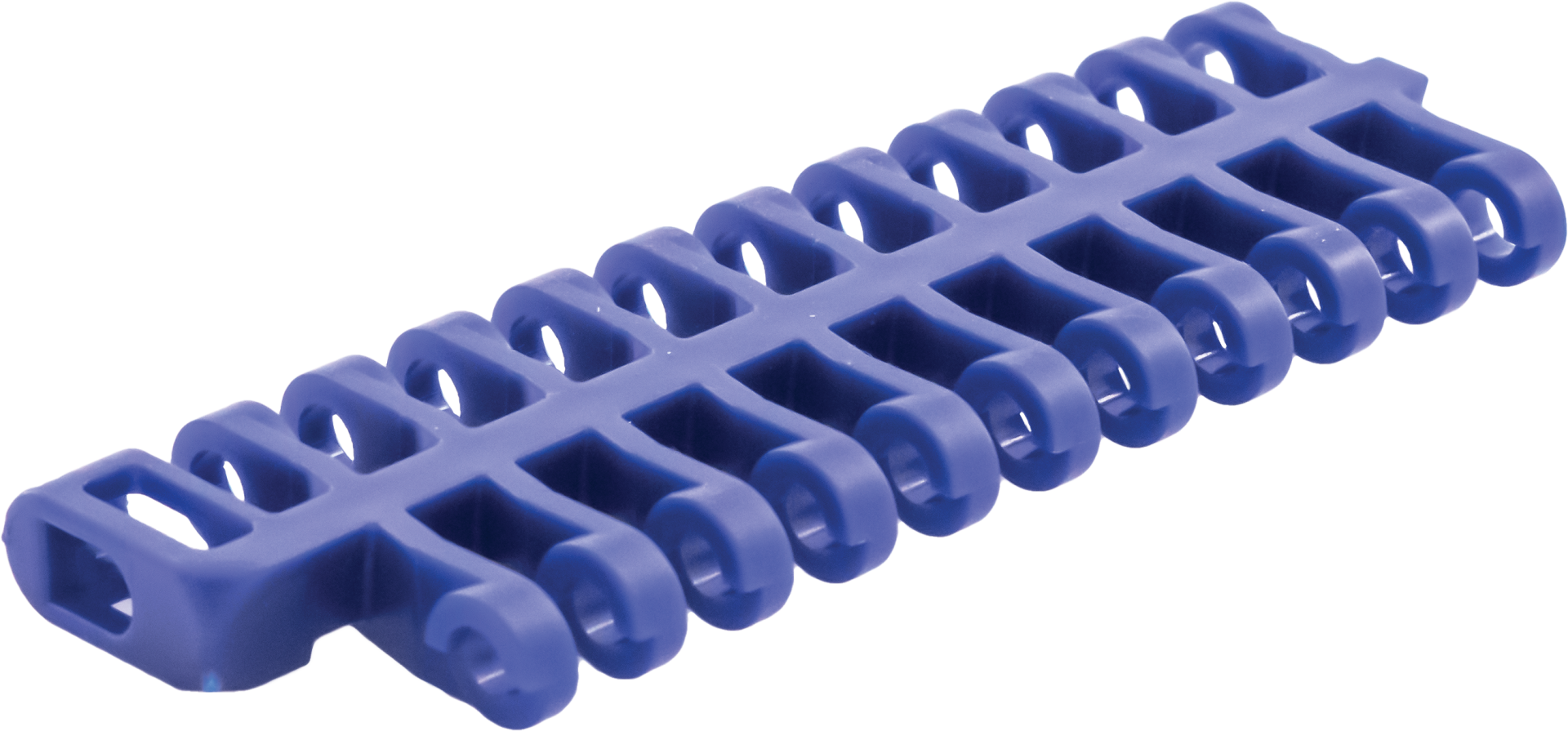

Heavy Duty 2.0” (50.8 mm) Pitch

Heavy Duty 2.5” (63.5 mm) Pitch

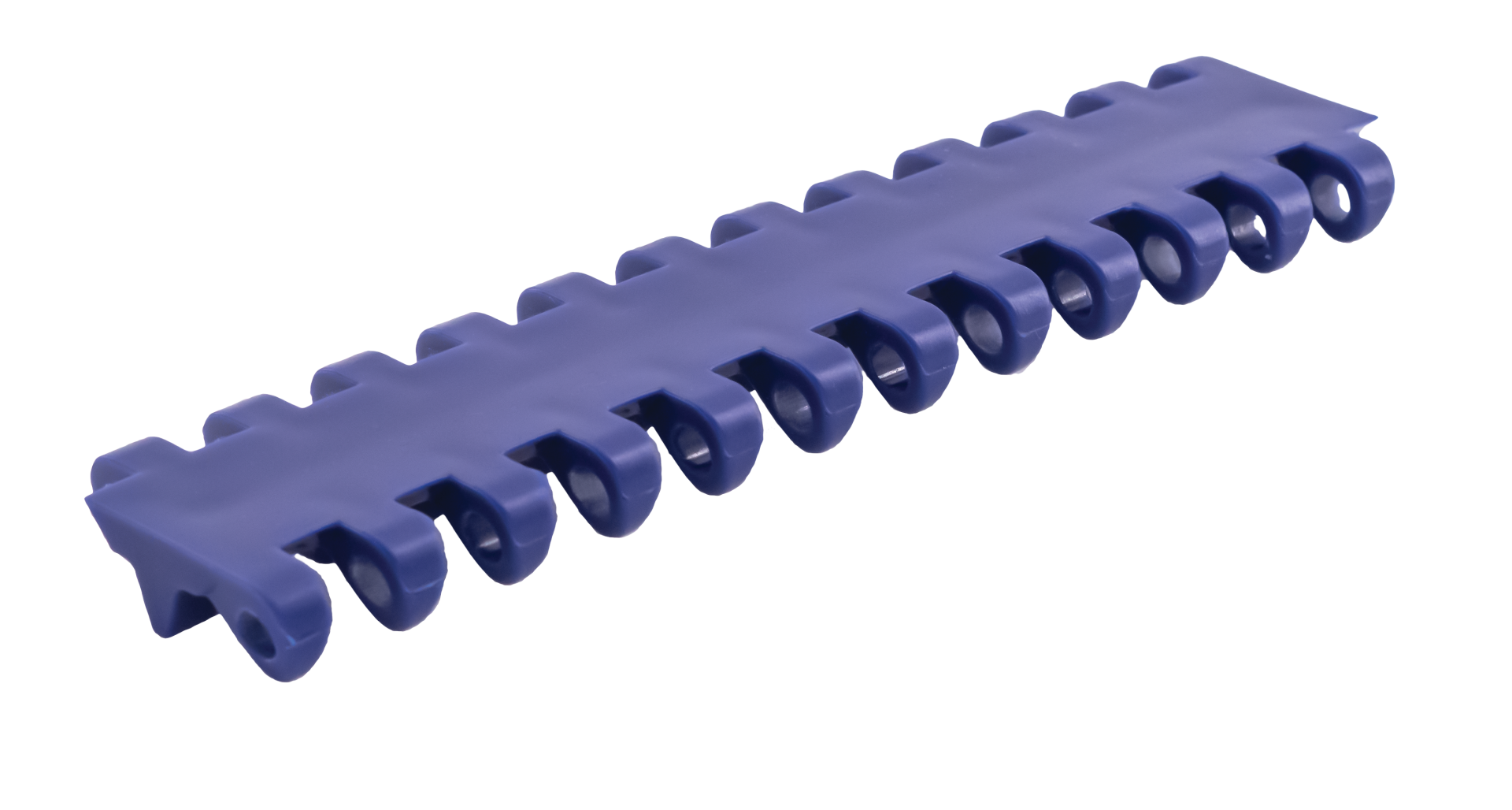

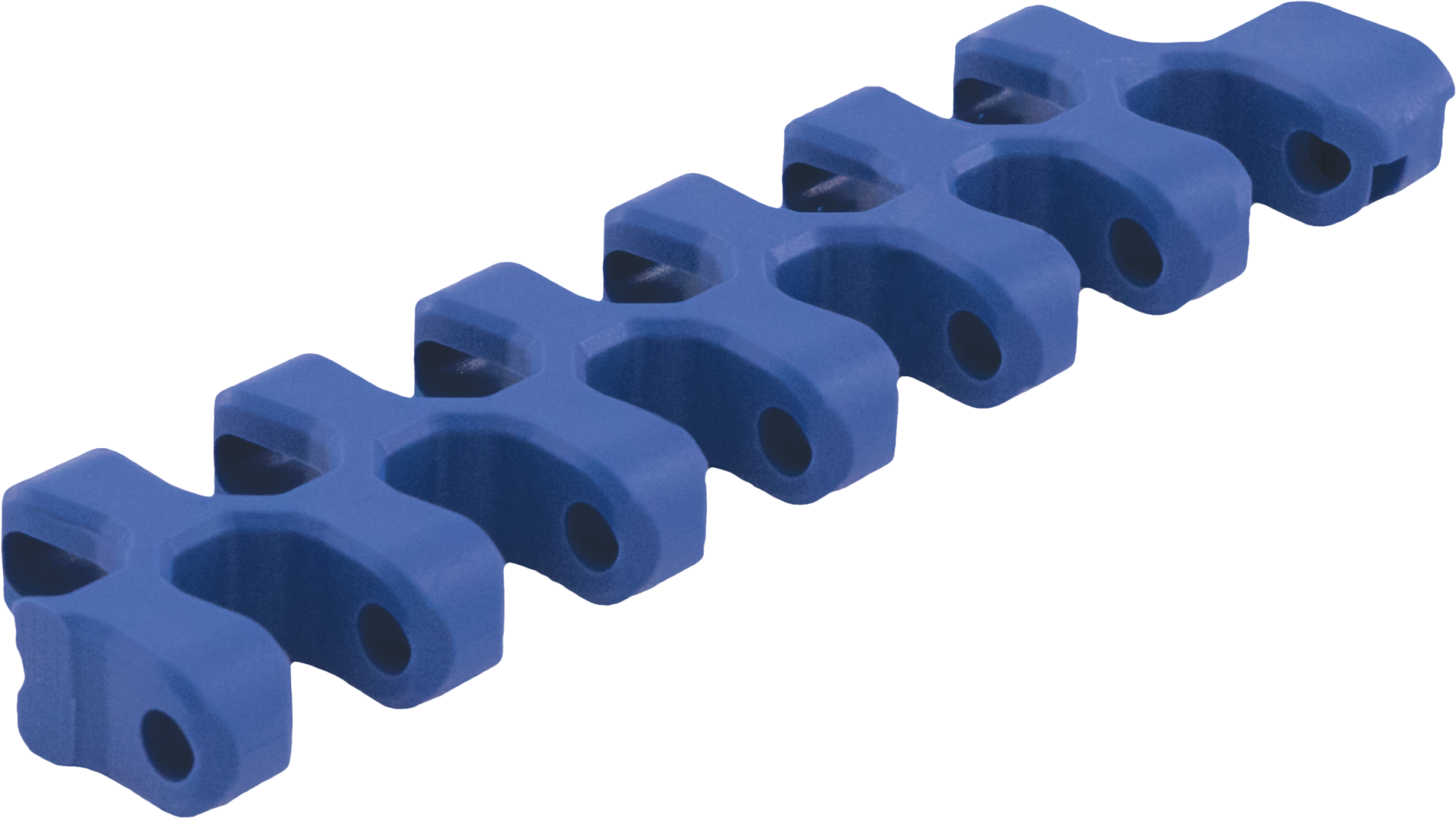

Radius 1.0” (25.4 mm) Pitch

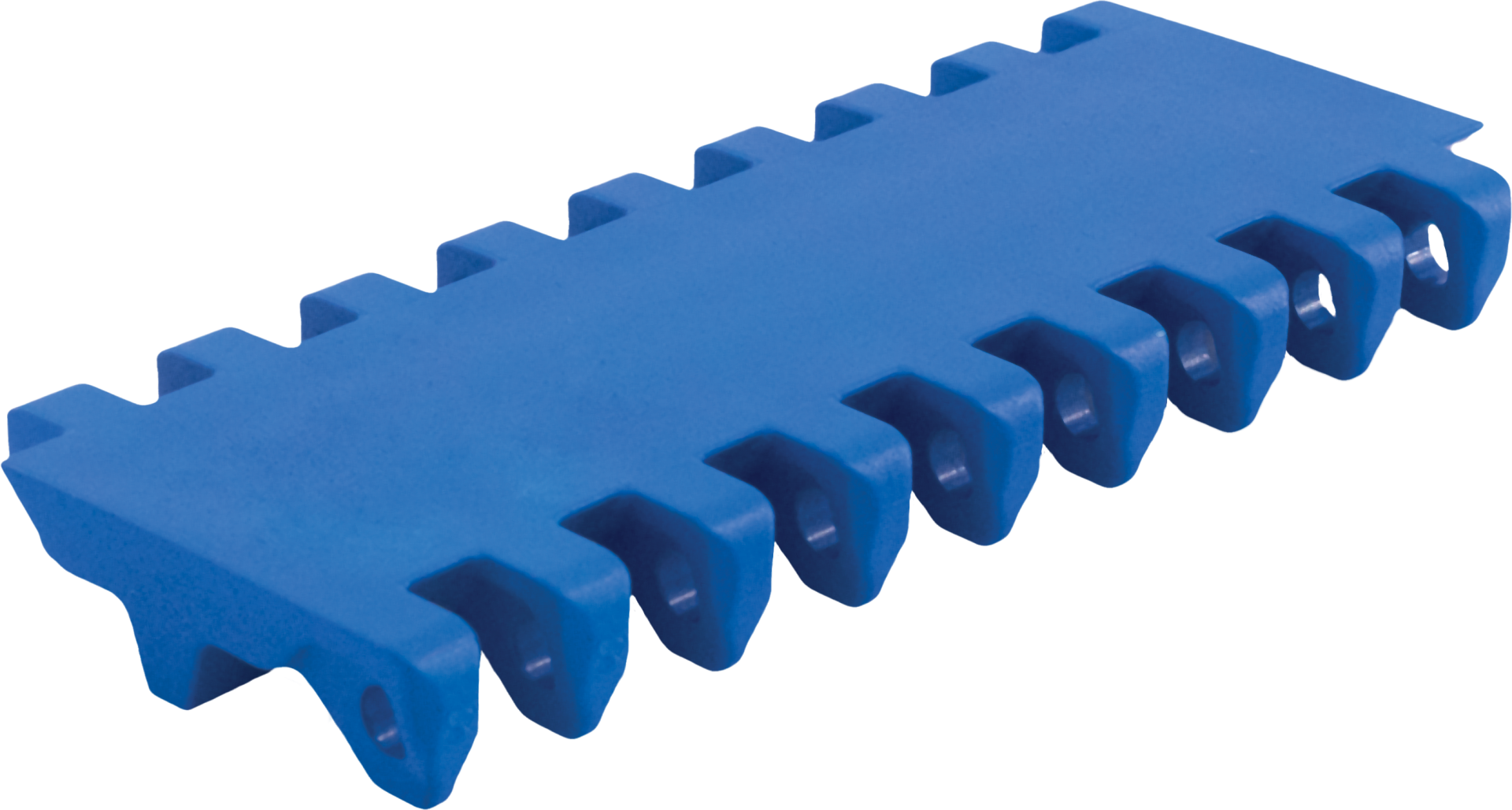

Standard Duty 0.60” (15.2 mm) Pitch

FINDEN SIE EIN VERGLEICHBARES SAFARI-PRODUKT

Die Kunststoff-Modulbändern von Chiorino sind zertifiziert, , um vollständige Sicherheit und Risikominimierung zu bieten. In Übereinstimmung mit den strengsten europäischen und internationalen Vorschriften, um sowohl die Betriebsabläufe der Kunden als auch die Gesundheit der Verbraucher zu schützen.